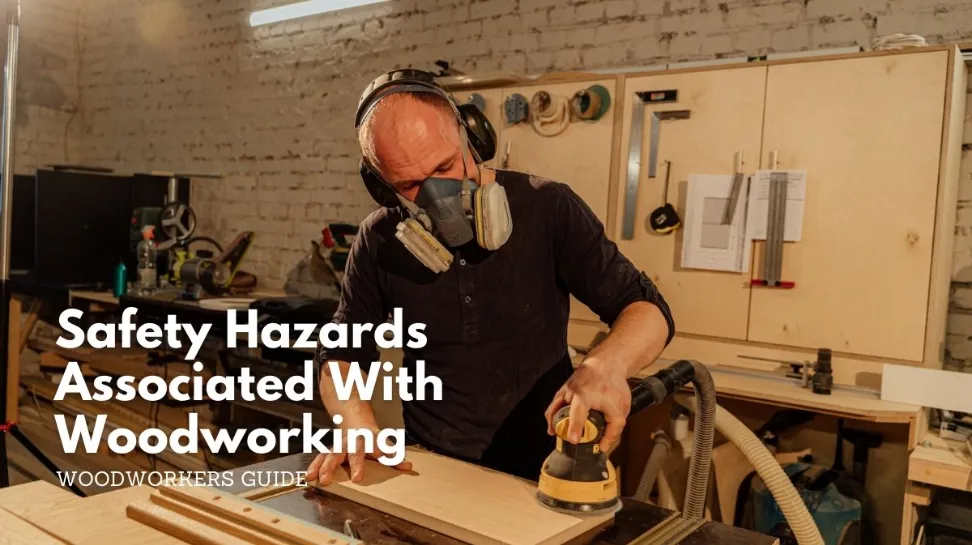

Safety Hazards Associated With Woodworking

Woodworking – a craft that requires precision, patience, and passion. But beneath the satisfying sound of chiseling and the sweet aroma of freshly cut wood, lies a hidden reality: a world of unseen dangers, lurking in every corner of the workshop. Every year, thousands of woodworkers fall victim to preventable accidents, resulting in injuries that can be devastating, disfiguring, and even deadly.

Woodworking is a high-risk activity that demands respect, attention, and a deep understanding of the hazards that come with it. From flying wood chips to toxic chemical exposures, the risks are real, and the consequences can be catastrophic.

In this article, I’ll expose the 10 most critical safety hazards associated with woodworking and provide you with the knowledge you need to protect yourself from the dangers in your workshop.

Table of Contents

10 Safety Hazards Associated With Woodworking

Here are 10 of the most common safety hazards associated with woodworking:

1. Flying Debris

When wood is cut, shaped, or sanded, small wood chips and particles will inevitably break off or become airborne posing a significant eye and face injury risk. This debris can reach high speeds depending on the tool being used, with some particles potentially moving faster than whiplash. Even small particles have enough force to puncture eyeballs or cause deep lacerations if they impact the face.

To protect yourself, always wear proper eye and face protection when performing any woodworking tasks. Look for ANSI-rated safety goggles that are specifically designed to prevent impact from fast-moving debris.

Related: Read our article on how to select the right woodworking safety glasses.

You should also consider a face shield to protect the entire face, as many injuries occur around the eyes and nose. Taking this small precautionary step is critical to prevent potentially permanent eye or facial injuries.

2. Hand and Finger Injuries

It is easy to take our fingers (I know I need mine) for granted but they are constantly at risk when using woodworking tools. Saws, planers, routers, and other power tools have very sharp blades that can easily slice through skin and bone if direct contact is made. A quick slip or lapse in concentration is all it takes for a serious injury to occur.

To avoid cuts, it is paramount to always keep hands away from blades by using push sticks, guarding mechanisms, or padded push blocks whenever a blade is exposed and in operation.

Gloves should always be worn but make sure to choose a non-slip style to avoid getting fingers pulled into machinery. Proper guarding and adherence to all safety procedures drastically reduce the risk of amputation or deep lacerations.

3. Kickback

Kickback is one of the most dangerous hazards in woodworking, occurring when wood contacts or gets pinched by the blade of a saw or jointer. This causes the wood to quickly thrust backward or sideways toward the operator, potentially causing severe cuts, lacerations, muscle pulls, or even broken bones.

Kickback is most likely to happen when wood binds the blade or when the material is twisted or cupped as it contacts the blade.

To prevent injury, always use proper guards, push sticks, and keep the blade or cutter guarded as much as possible. Feed material with caution and maintain full control at all times.

4. Dust and Fumes

Sanding, cutting, and planing wood creates large amounts of dust particles that can remain suspended in the air for long periods if proper ventilation and dust collection are lacking. Breathing this fine dust has been directly linked to nasal sinus cancers and serious lung diseases like pneumonia and bronchitis over long-term exposures.

Using a dust mask or respirator rated for microscopic particles is essential when performing any dusty woodworking tasks. It is also critical to have adequate dust collection systems attached directly to power tools as well as proper workshop ventilation to continuously clear dust from the air.

5. Noise Exposure

Powered woodworking tools like table saws, planers, and sanders generate loud noise that exceeds safe exposure limits. Prolonged or repeated exposure to high decibel levels over time can cause permanent noise-induced hearing loss.

Hearing protection like earplugs or earmuffs help guard against this but must be worn anytime operating loud tools or machinery. Look for hearing protection rated for the expected decibel level of the tools being used. It’s also important to keep others out of the work area when noisy tools are running to avoid bystander hearing damage.

6. Improper Lifting and Carrying Techniques

Woodworking materials like sheet goods and lumber can be quite heavy and handling them incorrectly puts the back and muscles at risk of strains or sprains. Always bend your knees and keep your back straight when lifting or lowering loads. Get help from others if objects are too heavy to safely handle alone.

Overhead lifting should especially be avoided. Use proper lifting straps, dollies, or carts designed for load distribution if significant weight is involved. Taking the time to safely maneuver heavy materials prevents unnecessary injuries that could sideline you from the shop.

7. Fire and Combustible Dust

Concentrations of small wood dust particles are highly flammable and can accumulate in machines. Even the smallest of sparks from power tools like table saws or drilling machines can easily ignite accumulated dust and cause an explosion if proper precautions are not taken. Every wood shop must have powerful dust collection systems installed, such as overhead ductwork that directs dust into a central collector.

All machinery should be equipped with dust ports for attachment to collection lines.

Areas must be thoroughly cleaned and vacuumed daily to prevent volatile dust levels from developing. Regular emptying and cleaning of dust collection units is a must to reduce the ever-present risks of fire.

8. Vibration

Prolonged use of vibrating tools like sanders, chisels, and polishers can lead to serious health issues over time if protective measures are not taken.

Hand-arm vibration syndrome is an occupational hazard caused by continuous or repeated exposure to vibrations. Symptoms range from temporary finger blanching and tingling to permanent nerve damage or loss of sensitivity.

The risks are higher for operators who use vibrating tools for several hours daily without breaks. Tool manufacturers have begun incorporating anti-vibration features like insulated handles and vibration-absorbing grip designs.

Taking micro-breaks of even just a few minutes every 30-60 minutes of continuous operation can help reduce the risk of long-term impacts on hands and arms.

9. Electrical Safety

Electricity is essential for powering wood shop equipment but brings serious risks if not handled properly.

All electrical systems and devices must use a qualified ground fault circuit interrupter to protect users from shock in the event of a short or malfunction. The wiring should be regularly inspected for signs of damage and repaired or replaced as needed.

Any electrical tools or machines must have intact, undamaged insulation on all cables and plugs.

It is also dangerous to use electrical devices in wet environments where water or moisture could conduct current and cause electrocution. Always be aware of overhead power lines and be careful not to bring any conductive materials into contact as improper grounding can otherwise have deadly consequences in a powered wood shop.

10. Chemical Hazards

Finishing wood products often requires the use of toxic substances like stains, paints, varnishes, and strippers containing solvents that emit hazardous fumes. Prolonged skin exposure to these chemicals can cause dermatitis while inhaling vapors poses respiratory risks like asthma.

It’s critical to apply finishing products in a well-ventilated area away from all ignition sources using Personal Protective Equipment (PPE) like gloves, a respirator, and goggles.

Products should be stored securely in their original, labeled containers away from areas accessible by children or pets. Manufacturers provide Safety Data Sheets with each product outlining exposure risks, first aid measures, and safe handling instructions that should always be followed to prevent harm.

Conclusion

In conclusion, woodworking can be an extremely rewarding hobby or profession. However, it is critically important to be aware of the various safety hazards involved and take appropriate precautions.

As we have explored in this article, injuries ranging from minor cuts and scrapes to more serious lacerations, amputations or even fatalities can potentially occur if proper safety practices are not followed.

While the list of 10 hazards presented here covers many common risks, it is not exhaustive. Continual education on new safety techniques, close monitoring of one’s workspace, use of safety gear, and following manufacturer’s guidelines are all necessary to prevent unnecessary harm.

Let safety be our top priority in all our woodworking endeavors from this point forward.

This article contains affiliate links #ad